Product Transfer Systems

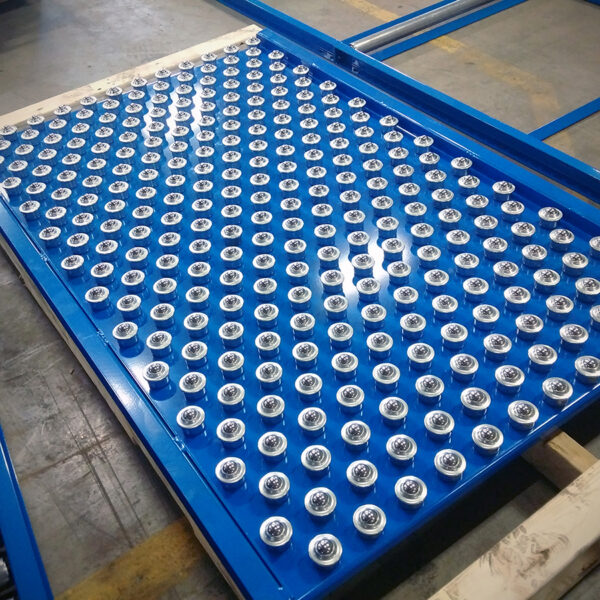

Ball Conveyor Systems

Ball Conveyor Systems are ideal for product lines where an operator needs to rotate or shift loads, or where multiple product lines meet. Ideal for manual rotation or repositioning of products moving along conveyor belts, the Ball Conveyor System can be used for standalone applications or be integrated into other conveyor systems, such as gravity conveyors, driven conveyors, or lift tables.

Highlighted Features

Integration with Other Conveyor Systems

Transfer skids along standard gravity or slider bed conveyors with an intermediate ball conveyor for operator ergonomics rotating a load 360˚ to perform their required duties

Multi-Directional Movement

Can connect multiple lines together, letting you move products more easily from one line to another

Endless Customization Options

From custom lengths and widths, to optional frame and ball materials, and various ball mounting selections, our Ball Conveyor Systems can meet the specific requirements of any application

Detailed Specs

- Facilitate multi-directional movement of products along conveyor lines

- Ideal for reorienting boxes, cartons, totes, and more

- Easy integration with other types of conveyor systems

- Durable steel channel frame

- Allow operators to easily rotate, remove, or sort materials and products

- Available in straight and curved sections with various ball centers to meet specific requirements

- Custom lengths and widths available

- Optional curves and spurs

- Optional frame materials include carbon steel powder coat painted or stainless steel

- Optional Ball materials include carbon steel, nylon, or stainless steel

- Optional housing materials include zinc plated carbon steel or stainless steel

- Ball Mounting Types: stud mounting, flange mounting, hole recessed mounting

- Metric Diameter Ball Transfers Available

- Optional floor supports available

Custom Designs Built to Meet Your Specific Requirements

Carney can also install ball conveyors on custom lift tables, tilt tables or other hydraulic ergonomic equipment. We are proud to offer custom designs built to meet your specific requirements.

Our optional add ons include custom lengths and widths, optional curves and spirs, optional ball materials including carbon steel, nylon or stainess steel, and optional floor supports. The ball mounting types include stud mounting, flange mounting or hole-recessed mounting.